Varumärke

Maskintyp

Din filtrering matchade inga resultat

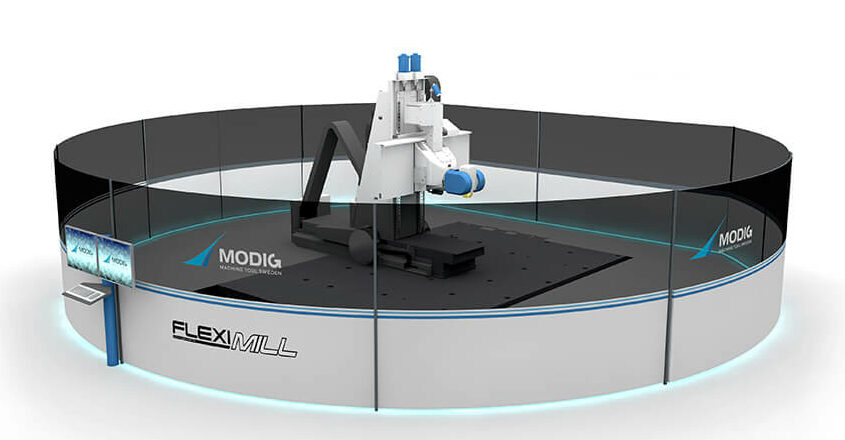

FlexiMill

FMT DUO

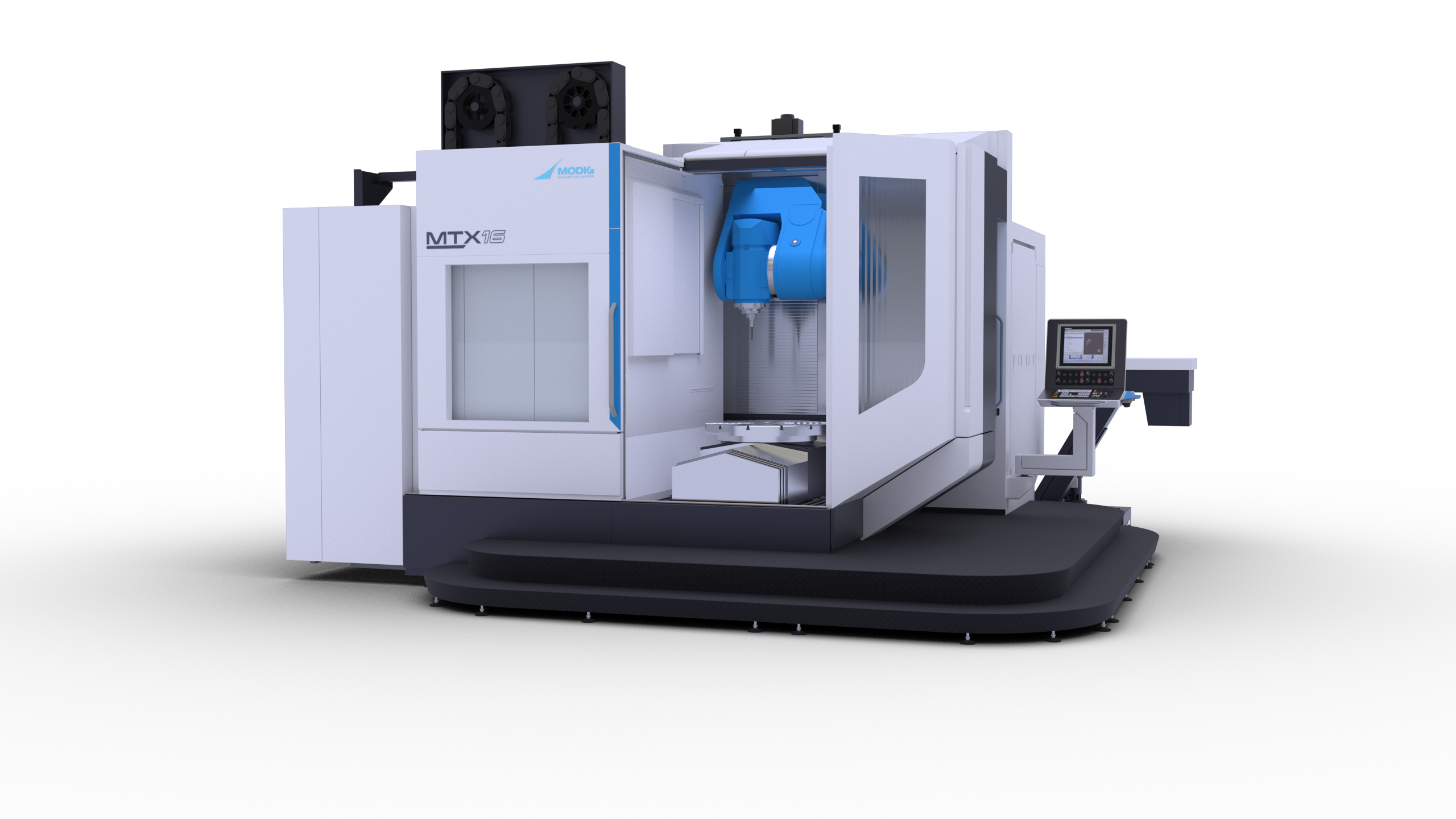

MTX

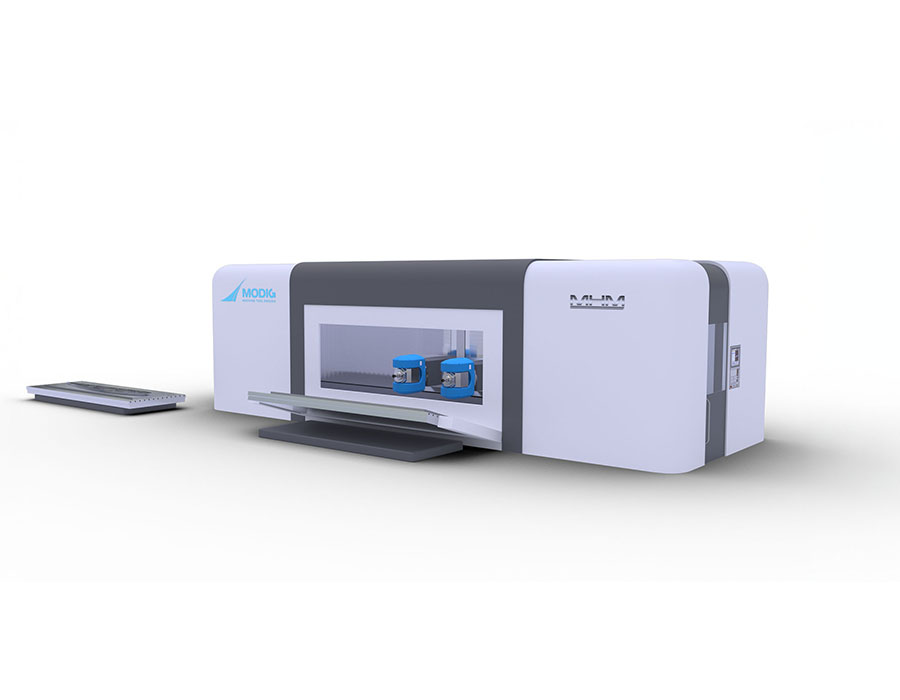

MHM

HHV DUO

HHV3

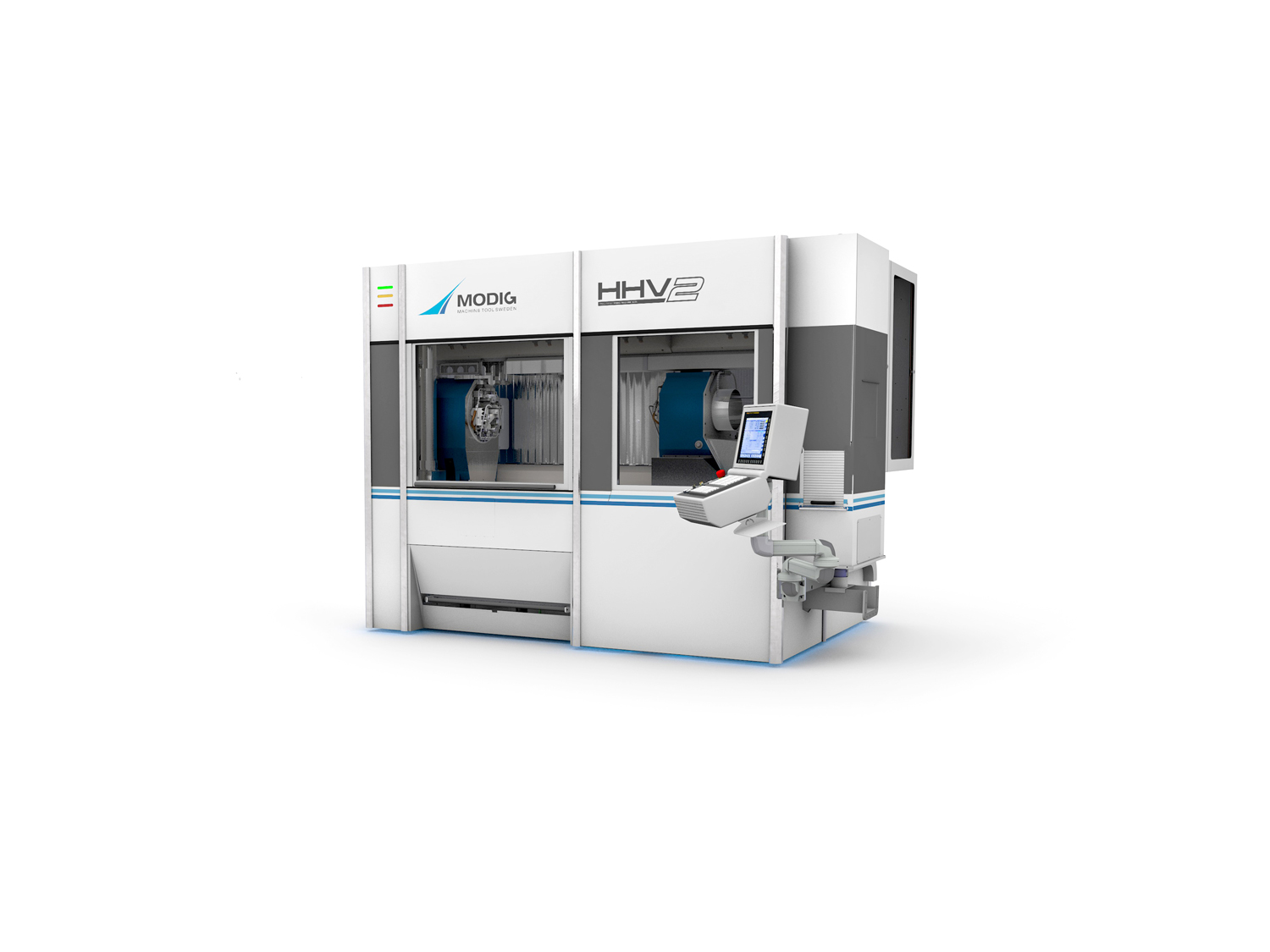

HHV2

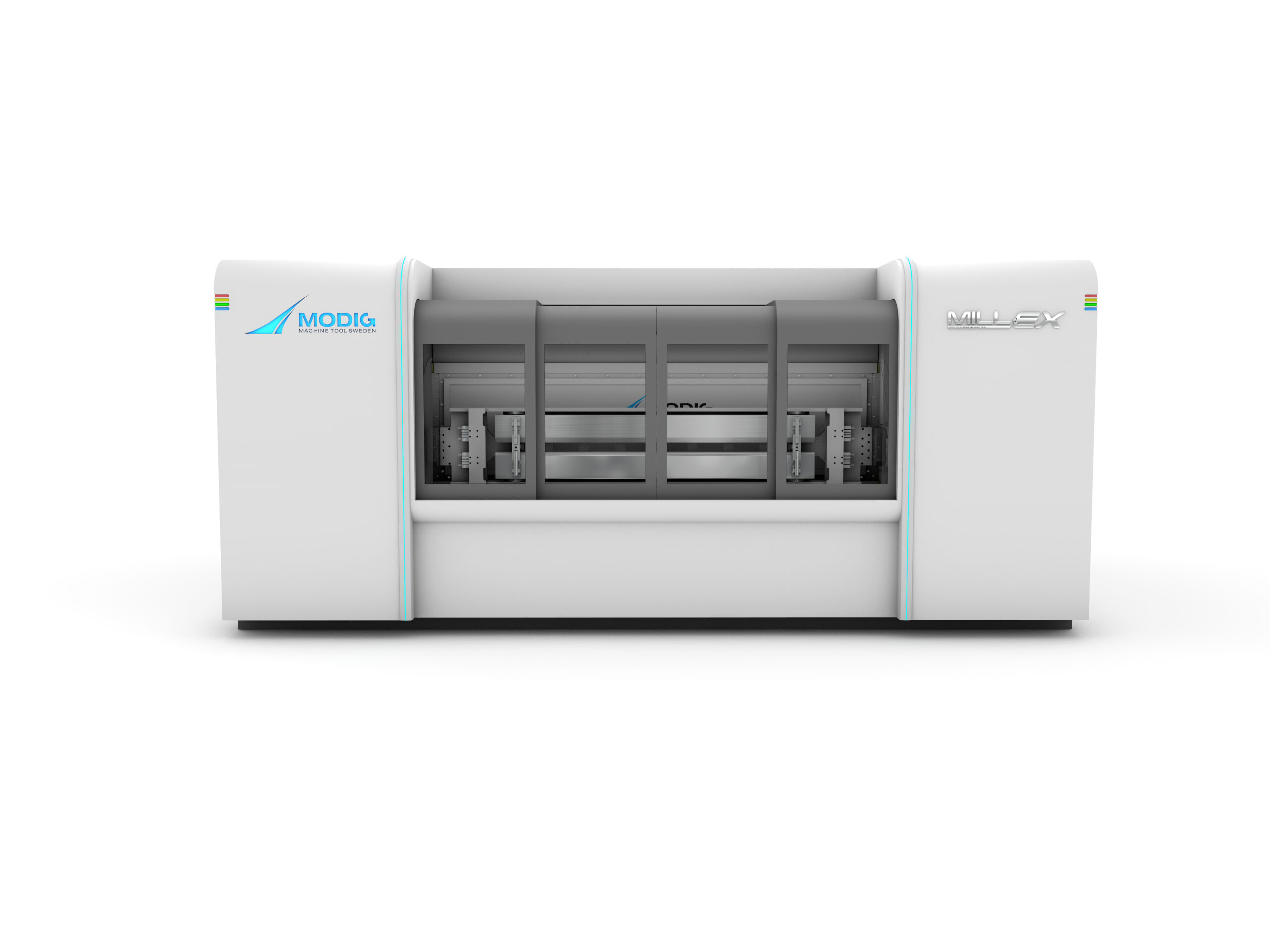

MILL-EX

MB-4000H

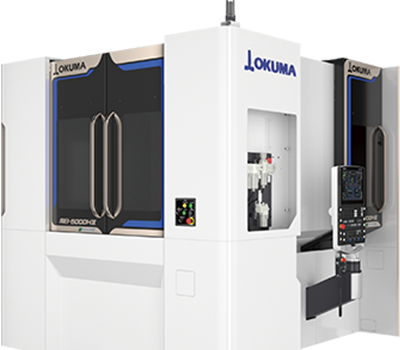

MB-5000HII

MA-400HA

MA-500HII

MA-600HIII

GENOS M460-VE-e

GENOS M560-V

GENOS M660-V-e

MU-400VII

MU-500VII

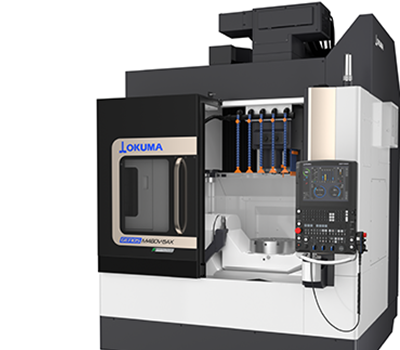

GENOS M460V-5AX

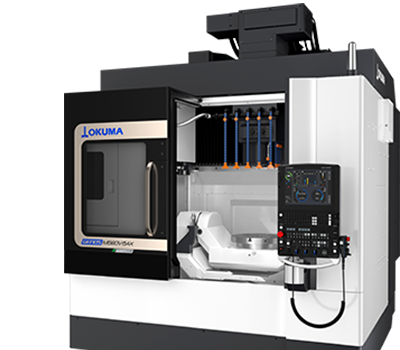

GENOS M560V-5AX

MU-4000V

MU-5000V

MU-6300V

MU-8000V

MU-10000H

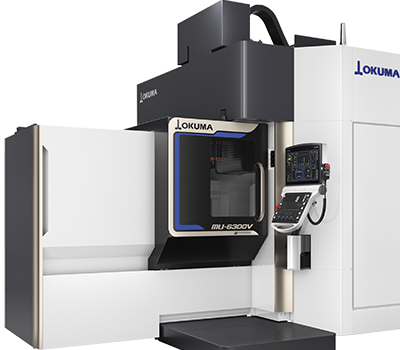

MU-S600V

UV Serien

DCV Serien

TV Serien

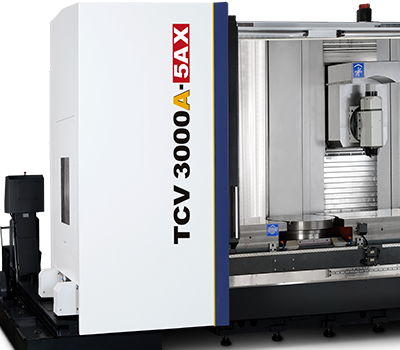

TCV Serien

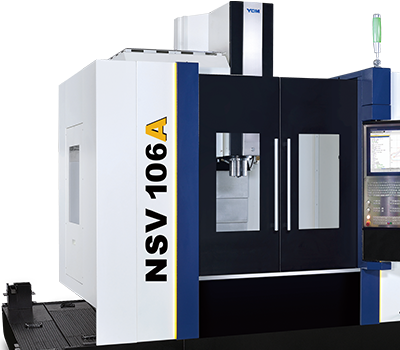

NSV Serien

NXV Serien

MU-8000V LASER EX

MU-6300V LASER EX

MU-5000V LASER EX

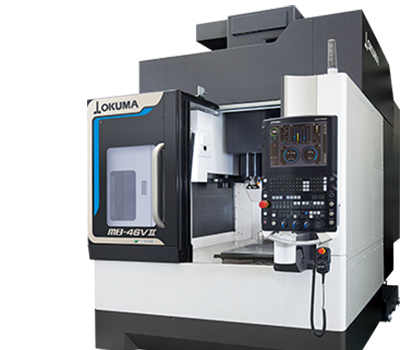

MB-46VII

T EXTREME

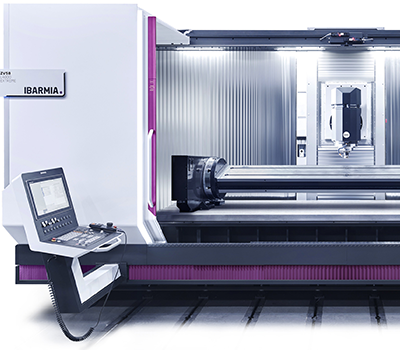

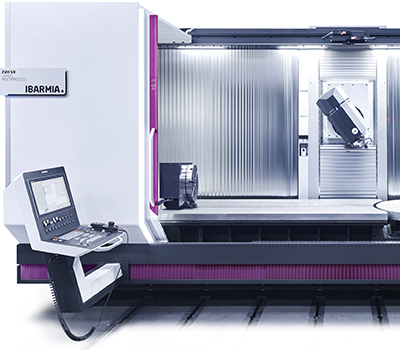

ZV EXTREME

ZVH STAR EDITION

ZVH EXTREME

ZVH MULTIPROCESS

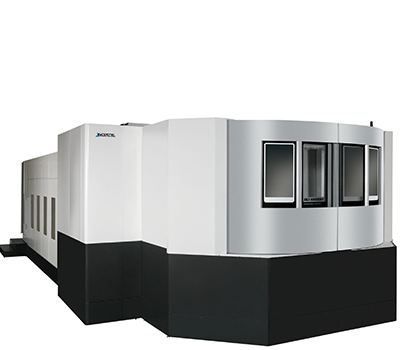

MB-10000H

MA-650VB

MA-550VB

MA-12500H

MA-8000H